PSP Astrobotics strives to advance robotic space technology through collaboration, innovation, and learning that enables students to impact space exploration

Current Project

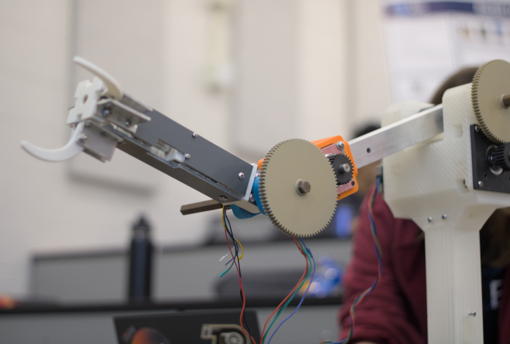

The project goal is to research and develop an autonomous robotic mechanism that analyzes and attaches onto objects in low earth orbit to perform In-Space Servicing Assembly and Manufacturing (ISAM) operations. ISAM is an emerging field within industry that ensures sustainable, versatile and innovative scientific advancement in space while allowing students to gain hands-on experience in R&D work. The team is currently focused on developing a robotic inch-worm arm with an attachment mechanism that will interact with a wide variety of objects. After attachment, the arm can perform multiple processes to deal with the target such as pick-and-place or manufacturing operations.

Subteams

Structures

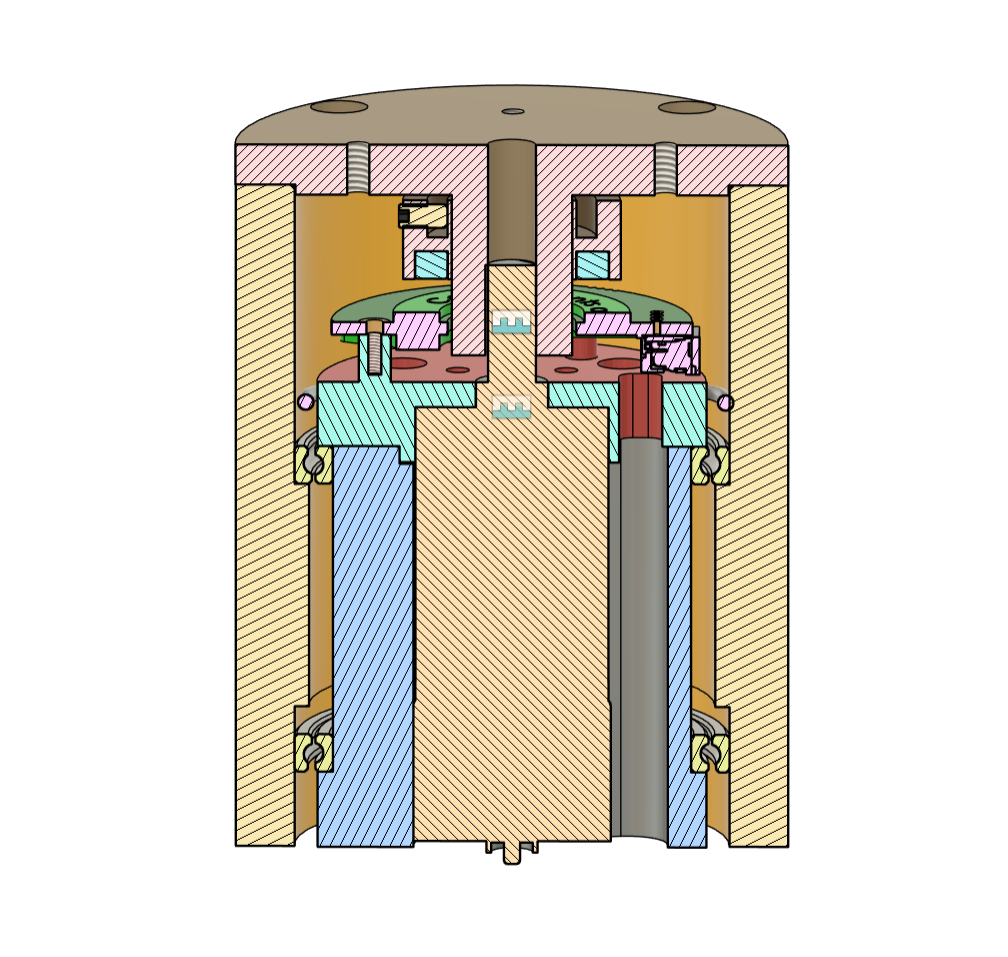

The Structures team is responsible for the design, analysis, and manufacturing of the mechanical subsystems within our robotic platforms. This includes conducting research and development to produce components capable of withstanding the extreme conditions associated with spaceflight. The arm features compact series elastic actuators to enable force feedback and precise motion control, and the end effector is designed with a modular tool-changer interface, allowing for adaptable interactions with various end-effectors and payloads. Structures works in close collaboration with the Electronics team to integrate hardware and develop the electromechanical functions required for autonomous operation.

The end effector is designed with a modular tool-changer interface, allowing for adaptable interactions with various tools and payloads. A twist-lock mechanism is utilized, acting as a universal tool attachment. Tools that are currently undergoing development include a screwdriver and electric screwdriver. A camera and light are used for visibility and AprilTag detection. Pogo pins are used for data and power transfer from the end effector to the connected tools.

Currently, the team is designing a 4 DOF arm to operate within a standard space station payload locker. This project focuses on developing systems capable of surviving launch loads while maintaining functionality in microgravity. The arm features custom actuators with high reduction, low speed motors for low power, high torque operation. Hollow bore absolute encoders at the gearbox output give precise feedback on actuator position, mitigating backlash error. Thin section angular contact ball bearings transfer axial loads during 1G test and keep the input and output assemblies aligned.

Electronics

The Electronics subteam designs, tests, and integrates the electrical systems that power, sense, and control our robots. We emphasize practical, end-to-end skills—members learn PCB design, collaborate across mechanics and software, and contribute directly to hardware that moves from bench to prototype. Our current focus is a 4-DOF arm for zero-gravity operations. Members design an actuator-control PCB in Altium, make thoughtful component choices, and assemble and bring up boards in structured soldering labs. The result is an end-to-end experience—from schematic to validated motion—while we advance the electronics and controls for space-relevant testing.

Software

The Software team is responsible for developing essential software that controls our arm, ensuring it can perform all its intended tasks effectively. Our work ranges from building computer vision models to designing control algorithms, all with the goal of giving the robot arm strong perception and reliable, precise movement.

One of the software team’s tasks is building a perception system that can autonomously detect objects and their depth in an environment. Currently, software team has built a pipeline that uses a monocular camera to detect the depth of an AprilTag. With this absolute depth information, we use deep learning to approximate the depth of the rest of the scene. Our next goal is to integrate this system with our robotics simulation, so we can move our system based on what it perceives autonomously.

Software is also responsible for simulating the arm, as well as the space environment in which the arm operates, for testing and analysis. Using CoppeliaSim, we simulate the physical interactions of the arm with its environment and with other objects it will interact with. Additionally, by using inverse kinematics models and ROS2 (Robot Operating System), the arm can be controlled to perform pick-and-place operations and other movement tasks.

Business

The Astrobotics Business Team fosters real-world relationships with competitive companies, ensuring strong industry connections and collaboration. Additionally, the team plays a crucial role in maintaining clear and effective communication with the community, promoting awareness, engagement, and support for our initiatives.